Mercury

Mercury

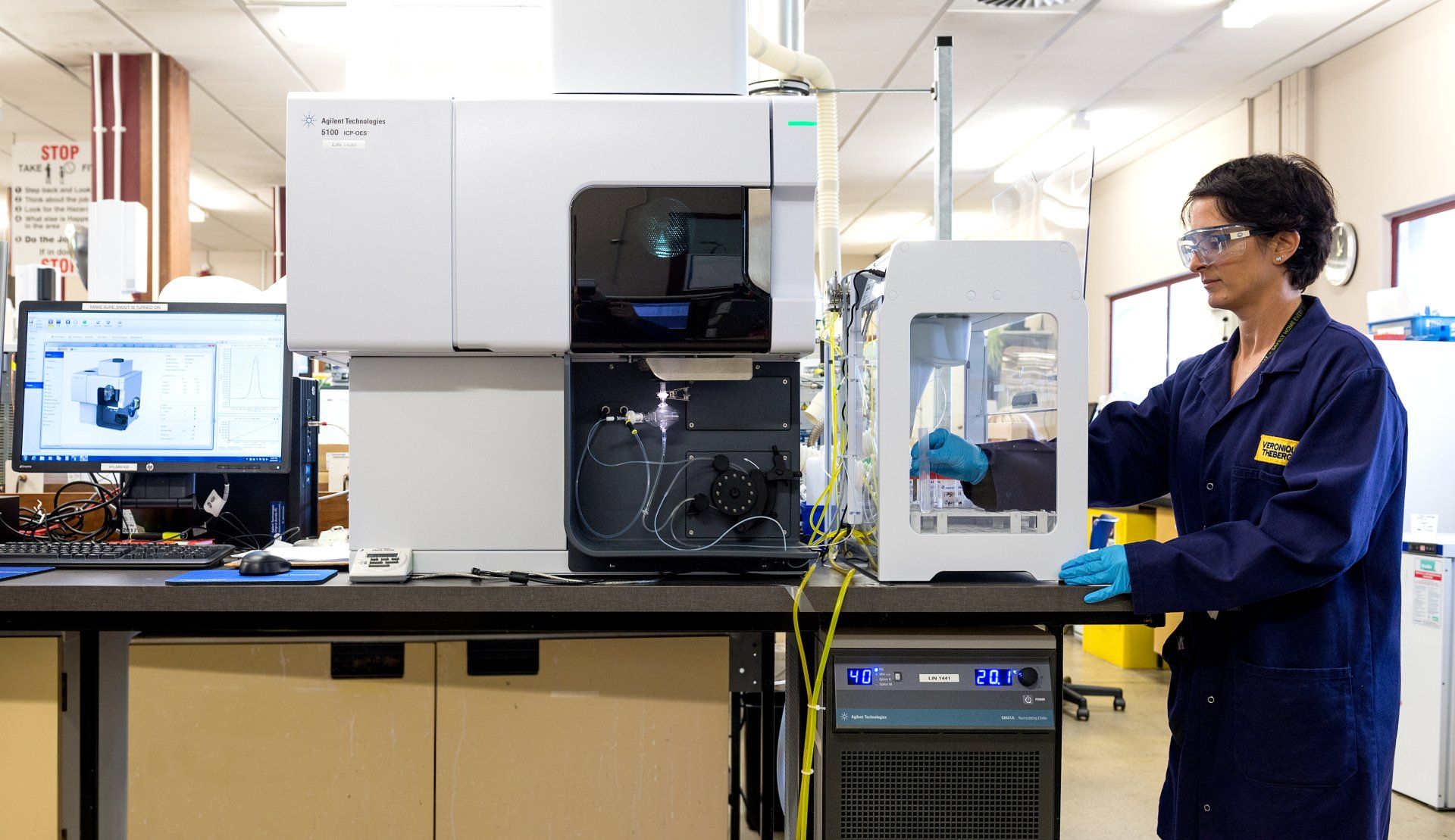

Testing for mercury can help avoid significant costs linked to equipment failure and help ensure exposure levels are minimised.

Mercury can be detrimental to both equipment and human health. Monitoring mercury levels is important to ensure exposure is minimised as it is toxic to life. It can also accumulate in process facilities and contributes to corrosion of some commonly used alloys - even at ppb levels.

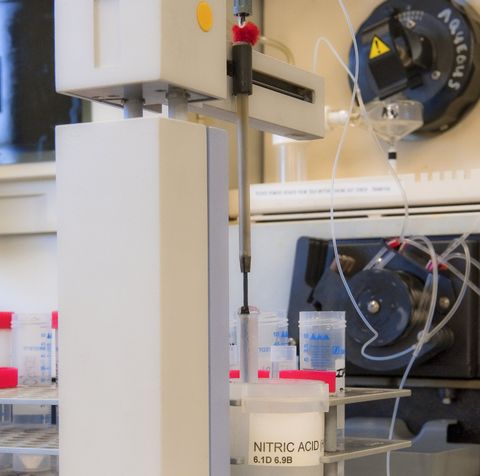

IPL measures “total mercury” including any insoluble mercury associated with particulate contaminants and speciation is available on request. IPL’s mercury capability allows for direct analysis of trace mercury to parts per trillion (ppt), sample matrix dependent.. Trace concentration of mercury to a sensitivity of 20ppt (ng/kg) is analysed in a wide range of sample types such as:

- Liquids

- Solids

- LPG

- Gases

We can supply Sulfinert coated pressure vessels to sample gas and LPG for subsequent mercury and hydrogen sulphide analysis.

Mercury analysis is carried out for various purposes including:

- Screening for quality control

- Troubleshooting for mercury speciation

- Identifying unknowns to help establish product value

- Preventative maintenance in refineries and production plants to identify catalyst poisoning

Turn around times

The technique we employ for mercury and trace mercury analysis is based on thermal decomposition and requires neither sample preparation nor waste disposal. This allows for fast turn-around times on results (generally 48hrs from sample receipt).