Bitumen rheology

Bitumen rheology

Bitumen rheology

What is rheology?

To put it simply, rheology is the study of the flow and permanent deformation of time-temperature dependent materials in response to an applied force. Given this basic definition, you can see how the rheology concept can easily be applied to bitumen and consequently our roads which get put through important variation of temperature throughout the seasons, years and force from the ever growing number of vehicles that travel on our roads.

How does the rheology concept apply to bitumen?

Bitumen rheology therefore corresponds to the measurements associated with the flow and deformation characteristics of bitumen. Understanding the bitumen rheology helps understand the pavement performance and how it is likely to “behave” and age through time. Foe example, is it susceptible to rut and bleed or to fatigue and crack.

IPL as a bitumen rheology specialist

IPL has worked with regulatory bodies, suppliers and customers to gain a comprehensive understanding of product specifications and has developed four (4) specific tests that provide additional data to help establish the bitumen rheology:

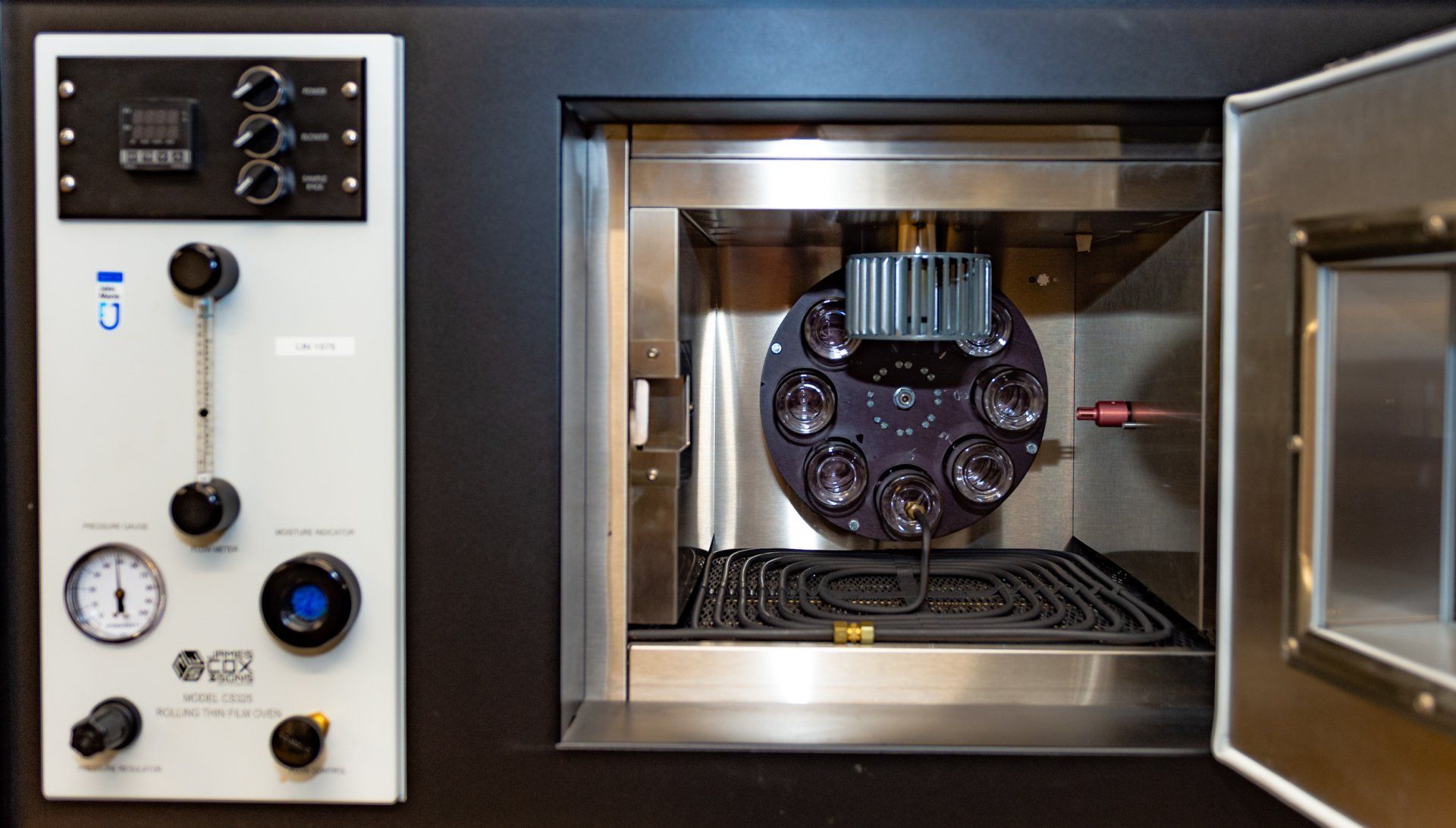

ASTM D2872 – Rolling Thin Film Over Test (RFTOT)

The RTFO conditioning process simulates the condition of the asphalt binder immediately after the pavement is constructed. This test method indicates approximate change in properties of asphalt during conventional hot-mixing at about 150oC as indicated by viscosity and other rheological measurements. It yields a residue which approximates the asphalt condition as incorporated in the pavement. RTFOT is intended to measure the effect of heat and air on a moving film of semi-solid asphaltic materials. This test method can also be used to determine mass change, which is a measure of asphalt volatility.

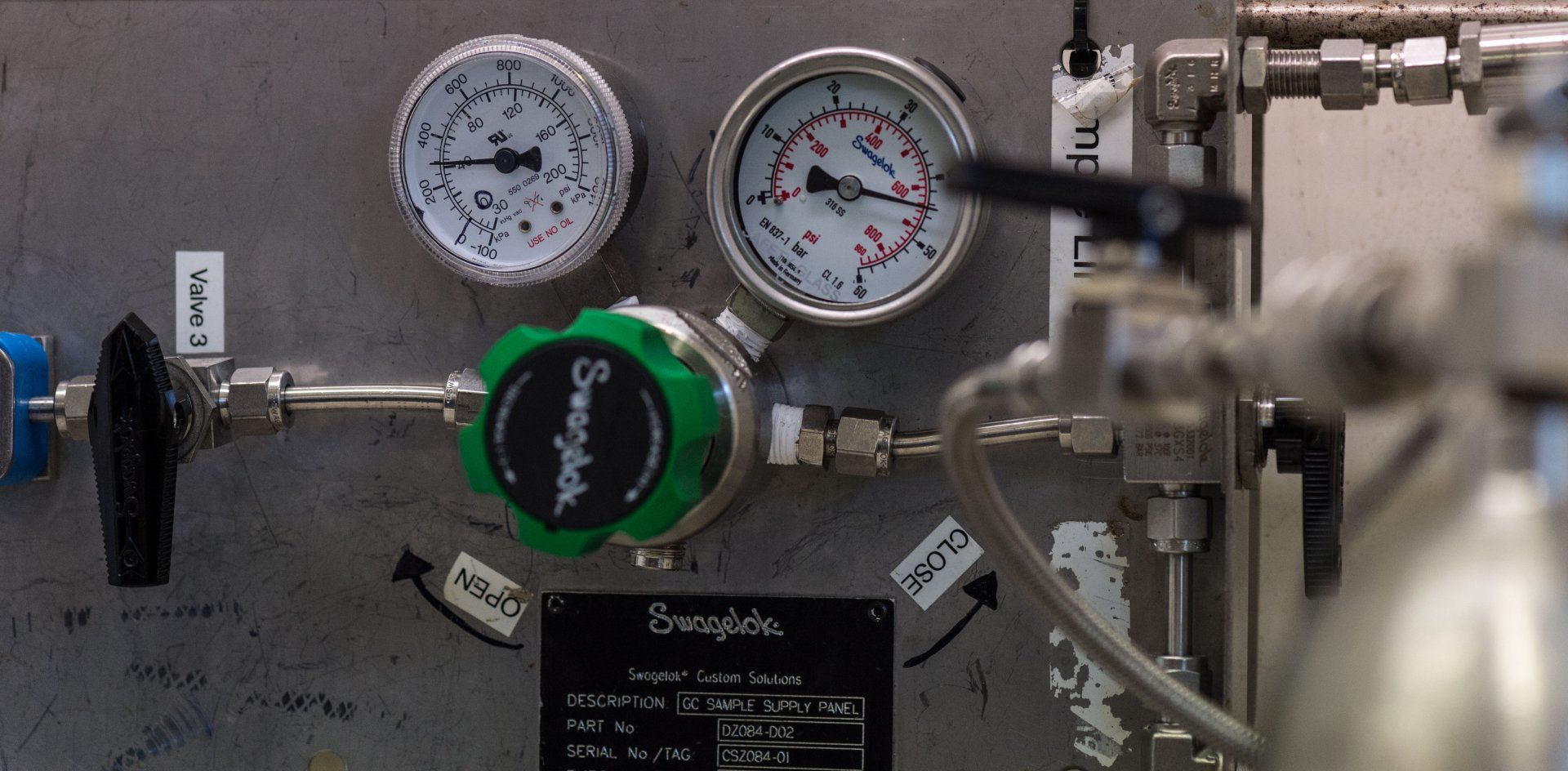

AASHTO T315 – Rheology of Asphalt and Bitumen by DSR

Dynamic Shear Rheometer (DSR) is one of the most important tests in the performance grade specification, the DSR test is used to determine the dynamic shear modulus and phase angle of asphalt at temperatures ranging from 6 to 88oC. The test is performed at 10 radians/second to simulate a wheel passing over the pavement surface at 88.5 Km/h. The complex shear modulus and phase angle together are used to characterize the binder at high and intermediate temperatures in order to determine the performance grade. The test temperature for this test is related to the temperature experience by the pavement in the geographical area for which the asphalt binder is intended to be used.

AASHTO T350 – Dynamic Shear Rheometer

This method covers the determination of percent recovery and the non-recoverable creep compliance of asphalt binders by means of Multiple Stress Creep Recovery (MSCR) test. The percent recovery value is intended to provide a means for determining the elastic response and stress dependence of polymer modified and unmodified asphalt binders. Nonrecoverable creep compliance has been shown to be an indicator of the resistance of an asphalt binder to permanent deformation under repeated load.

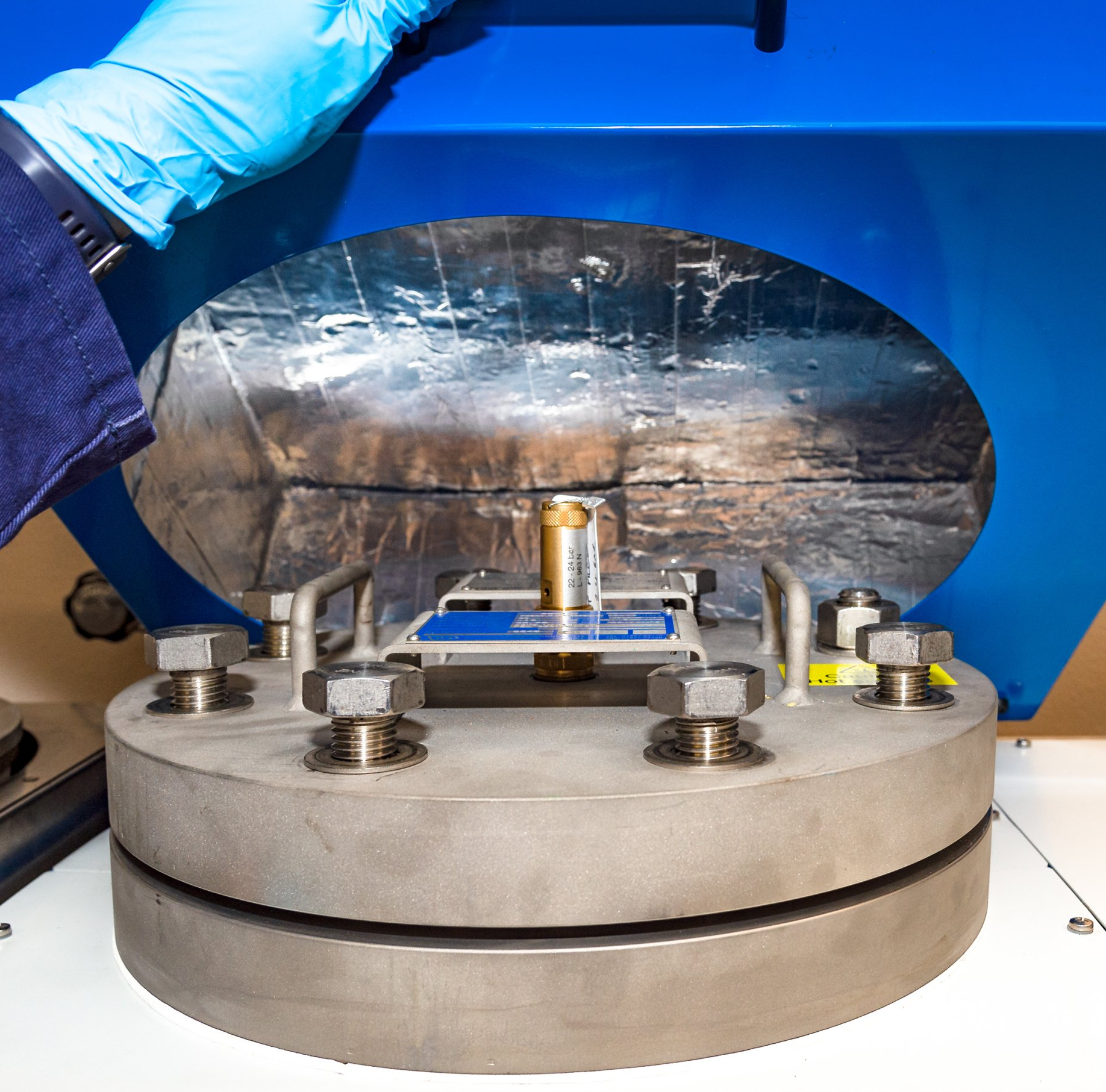

ASTM D6521 – Accelerated Aging of Asphalt Binder

This standard practice is used for conditioning asphalt binder by subjecting the sample to higher temperature and pressure. This method simulates in-service long-term aging of asphalt/ binders. The test procedure mimics 5 to 10 years of in-service aging of asphalt binder.

Back to Bitumen webpage

IPL has refurbished part of their Northland lab to incorporate & provide bitumen rheology capabilities. These tests are now up and running and are able to establish whether the bitumen manufactured or imported into NZ, complies with the new performance based M1-A specs in NZ.

other related services

Petroleum Products Testing

Petrol / Gasoline Testing

Diesel / Automotive Gas Oil Testing

Aviation Fuels Testing

Marine and residual Fuel Oils Testing

Gas and Pressurised Gas Analysis

Biofuels Analysis

Dedicated to providing quality lab testing services

About IPL

Established in July 1999, Independent Petroleum Laboratory Limited (IPL) is a fully independent laboratory that provides specialist Fuels, Biofuels, Industrial and Environmental laboratory testing services to a wide range of customers throughout New Zealand and the South West Pacific.

Get the latest information and promotions in your inbox

Newsletter

Thank you for contacting us.

We will get back to you as soon as possible.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

Please try again later.

© 2024

IPL : Website Design Auckland by Fuel Design Ltd